OEE Calculator

OEE Calculator

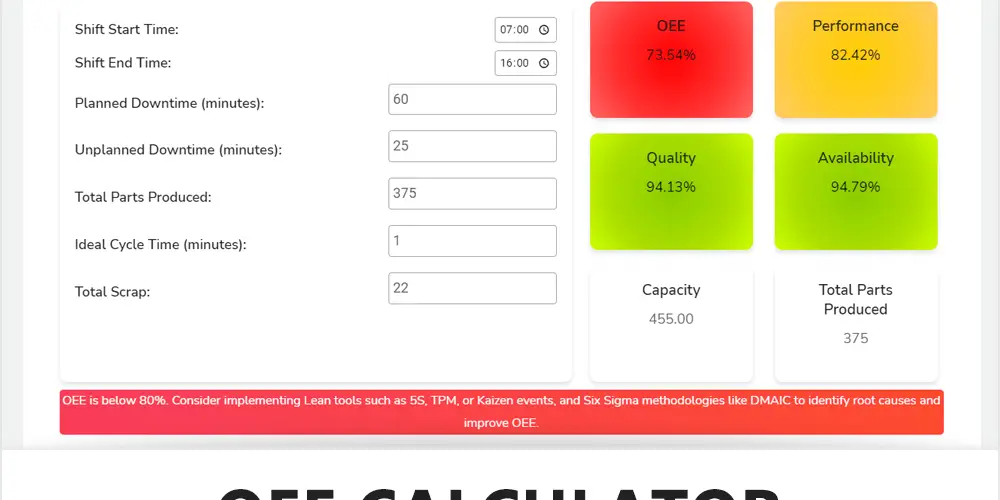

OEE

Performance

Quality

Availability

Capacity

Total Parts Produced

How to use the OEE Calculator:

Input Shift Start and End Times: Enter the start and end times of the shift in the corresponding fields using the 24-hour format (e.g., 07:00 or 15:00). The calculator will use this information to determine the total shift duration.

Input Planned Downtime: Enter the total duration of planned non-production events (e.g., breaks, meetings, scheduled maintenance) during the shift, in minutes.

Input Unplanned Downtime: Enter the total duration of unexpected non-production events (e.g., equipment failures, material shortages) during the shift, in minutes.

Input Total Parts Produced: Enter the total number of parts produced during the shift, including both good and defective parts.

Input Ideal Cycle Time: Enter the time it takes to produce one good part under optimal conditions, in minutes. Be as precise as possible (e.g., use two decimal places).

Input Total Scrap: Enter the total quantity of scrap material or parts that cannot be reused or reworked, generated during the shift.

Calculate OEE: After entering all the required information, the Overall Equipment Effectiveness (OEE) will automatically calculate the OEE. The calculator will display the OEE as a percentage, along with the individual components: Availability, Performance, and Quality as well as Capacity vs Total parts produced.

Interpret Results: Use the OEE percentage and its components to identify areas for improvement in your production process. A high OEE indicates efficient production, while a low OEE may signal issues with availability, performance, or quality.

Remember to always validate the input data and verify the results to ensure accuracy. The OEE Calculator is a helpful tool for identifying inefficiencies and opportunities for improvement, but it should be used alongside other data analysis and process improvement methods.

How is OEE Calculated:

Overall Equipment Effectiveness (OEE) is a metric that assesses the efficiency of a manufacturing process by taking three critical factors into account: availability, performance, and quality. These three components are multiplied together to calculate it. Here is a brief explanation of each component, as well as an example of how OEE is calculated:

Availability: This factor measures the percentage of scheduled production time that the equipment is actually available for operation. It is calculated as follows:

(Total Scheduled Time – Downtime) / Total Scheduled Time = Availability

For example, if a shift is scheduled to last 480 minutes (8 hours) and has 60 minutes of downtime (both planned and unplanned), the availability is:

(480 – 60) / 480 = 420 / 480 = 0.875 or 87.5% availability.

Performance: This factor measures the speed at which the equipment is operating compared to its optimal speed. It is calculated as follows:

Total Parts Produced * Ideal Cycle Time = Performance (Total Scheduled Time – Downtime)

For example, if 950 parts are produced during the shift at an ideal cycle time of 0.50 minutes per part, the performance is as follows:

(950 * 0.50) / 420 = 475 / 420 = 1.131 or 113.1% performance

It should be noted that if the equipment runs faster than its optimal speed, the performance can exceed 100%.

Quality: This factor calculates the percentage of good parts produced out of all parts produced. It is computed as follows:

Quality = (Total Parts Produced – Total Scrap) / Total Parts Produced

For example, if there are 50 scrapped parts, the quality would be:

Quality = (950 – 50) / 950 = 900 / 950 = 0.947, or 94.7%

Calculate OEE: Add the three components together to get the OEE:

OEE = Availability * Performance * Quality

Using the example values, the OEE would be:

OEE = 0.875 * 1.131 * 0.947 = 0.928 or 92.8%

The OEE in this example is 92.8%, indicating that the manufacturing process is efficient. A higher OEE percentage indicates a more efficient manufacturing process, whereas a lower percentage may indicate areas for improvement in availability, performance, or quality.

Industry Standard OEEs:

The industry standard for OEE is often around 85% or higher, indicating a well-managed and efficient manufacturing process. However, it is critical to recognise that OEE benchmarks can vary greatly depending on the industry and the specific manufacturing process in question.

Here are some examples of typical industries and their average OEE percentages:

Automotive: The automotive industry, which is known for its highly automated production lines and lean manufacturing practises, frequently achieves OEE levels of 75% to 85%.

Food and Beverage: This industry has a wide range of processes, from simple packaging lines to complex cooking and processing systems. The average OEE value is lower, ranging between 65% and 75%.

Pharmaceutical: Due to stringent quality requirements and a focus on regulatory compliance, the pharmaceutical industry may have OEE levels ranging from 70% to 85%.

Consumer Packaged Goods (CPG): OEE values in the CPG industry can range from 65% to 75% because manufacturing processes can range from simple to complex, with varying levels of automation and customization.

Heavy Industry: The nature of the processes, equipment, and maintenance in industries such as steel, pulp and paper, and cement can result in lower average OEE values, typically ranging from 60% to 75%.

It is important to note that these are only guidelines; each company should develop its own OEE benchmarks based on its unique processes, equipment, and industry. Aiming for a higher OEE is always a good idea because it drives continuous improvement and identifies areas where efficiency can be improved further.

A: OEE stands for Overall Equipment Effectiveness. It’s a standard metric used in the manufacturing industry to assess the performance, quality, and availability of a manufacturing process. OEE is calculated by multiplying the three individual metrics: Availability, Performance, and Quality.

A: OEE is calculated using the formula: OEE=Availability×Performance×Quality Where:

- Availability is the ratio of actual production time to planned production time.

- Performance measures how fast the process runs compared to its maximum speed.

- Quality represents the good units produced as a percentage of the total units started.

A: OEE is crucial because it provides a comprehensive measure of how well manufacturing operations are performing. A high OEE score indicates that a manufacturing process is running close to its full potential, producing quality products at the maximum possible rate. On the other hand, a low OEE score can highlight areas of inefficiency, which can then be addressed to improve productivity and reduce waste.

A: While an OEE score of 100% represents perfect production (no downtime, no defects, and maximum speed), in reality, such a score is challenging to achieve. Generally, an OEE score of 85% or higher is considered world-class for discrete manufacturers. However, it’s essential to set realistic OEE targets based on industry benchmarks and the specific processes of a manufacturing facility.

A: Improving OEE involves addressing inefficiencies in the three components: Availability, Performance, and Quality. Some strategies include:

- Regular maintenance to reduce equipment breakdowns and unplanned downtime.

- Training operators to ensure consistent operation and reduce variations.

- Implementing quality control measures to detect and prevent defects.

- Using real-time data to monitor and analyze performance, allowing for quick adjustments.